Safety Viewpoint development

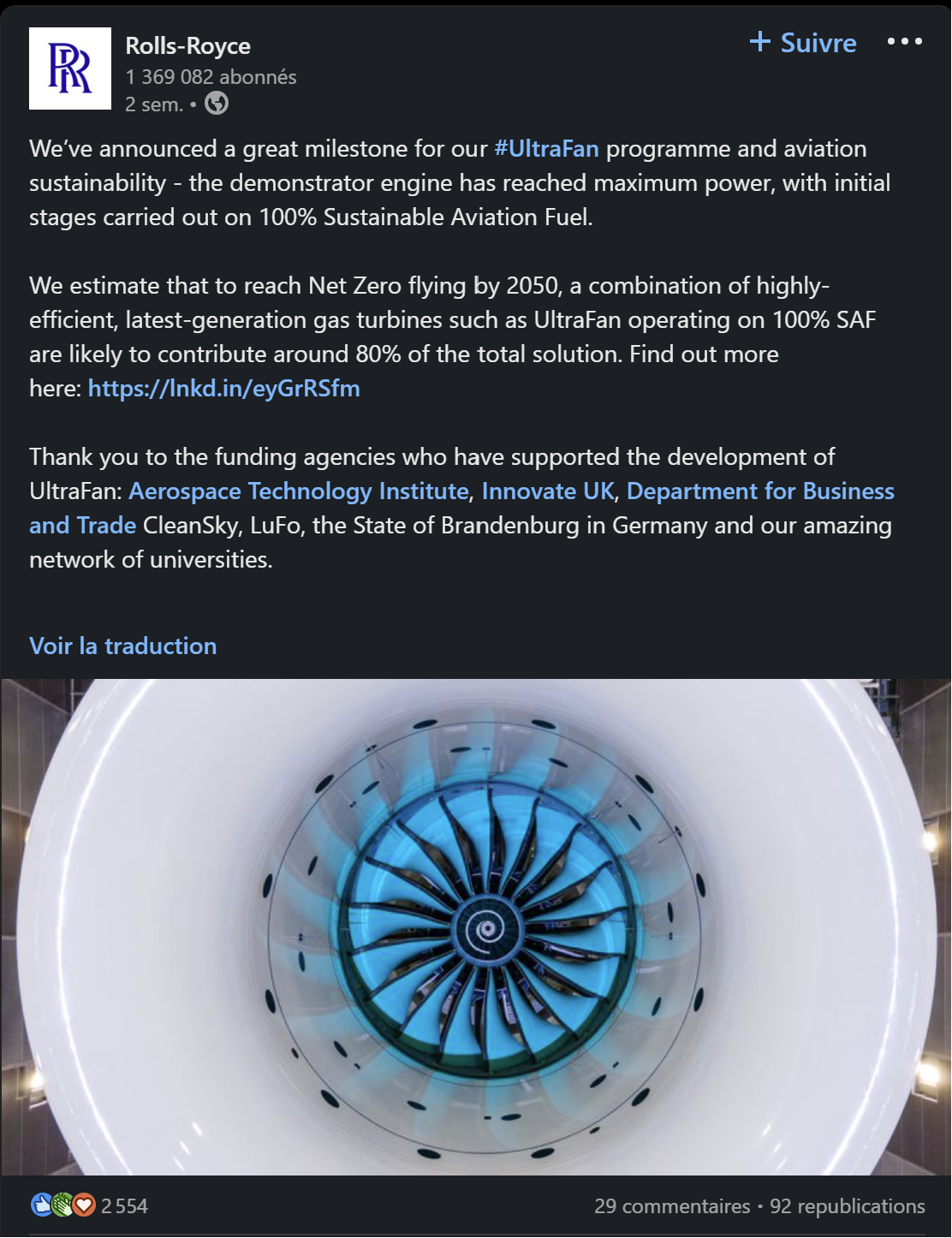

Rolls-Royce develops and delivers complex power and propulsion solutions for safety-critical applications in the air, at sea and on land, including the world’s most efficient large aero-engine, the Trent XWB.

The global Rolls-Royce team is pushing innovation like never before. The UltraFan™ is a new generation of engine to power short-haul and long-haul aircraft. The UltraFan™ features a new geared architecture (a power gearbox introduced between the fan and the turbine) to ensure that the fan, compressors and turbines all run at their optimum speed improving overall performance.

Future developments of this architecture will be architected and designed using an MBSE approach with Capella, along with multiple cutting-edge technologies such as hydrogen-combustion.

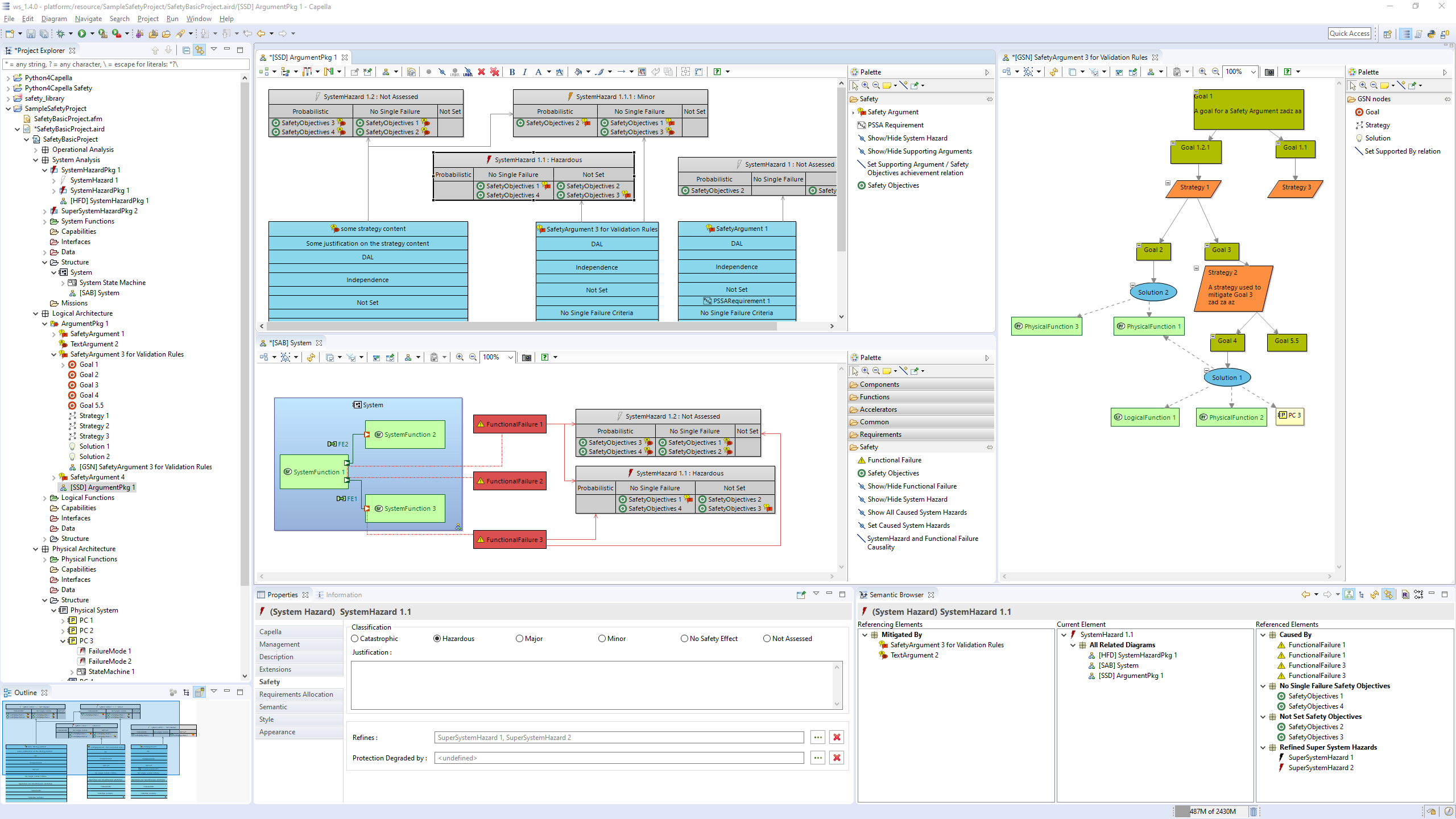

To integrate safety processes directly into Capella, Rolls-Royce initially created a prototype add-on. The add-on is expected to bring benefits through a closer integration of system design and safety, and a crystal-clear line of sight to system safety within the design community. This add-on relies on the integration of ARP4761 and 4754A safety concepts throughout the different architecture levels of the ARCADIA methodology, and their attachment to the base Capella model elements. Visually intuitive diagrams allow the user to review and capture safety strategies at the different levels of architecture description.

How can we industrialize the safety add-on and make it a production ready solution?

Rolls-Royce called upon Obeo to industrialize the add-on prototype by making it a production-ready solution.

This project focused on creating a Capella extension for representing safety-related concepts. The primary goal was to demonstrate linkage between system Hazards and system design elements, driving the elicitation of derived requirements through a structured approach to developing safety strategies. Additionally, there is the new ability to model failure modes within the design, allowing designers to validate their strategies are complete before investing in costly implementation of safety-critical software and hardware. The developed add-on allows the user to draw the relations between the safety-related concepts and the Capella model, and represent them on both legacy Capella diagrams and new diagrams.

As requested, Obeo proposed carrying out the project through an agile approach: successive sprints of implementation of more and more features with a usable result delivered regularly. The usable result was validated by Rolls-Royce, and the result of this validation fed into the next sprint. The agile approach also allowed us to develop unplanned features that were identified during the development.

“Our experience with Obeo was positive from start to finish. They were flexible, very competent in agile software development and clearly had comprehensive knowledge of the Capella workbench, EMF and User Experience design. We worked directly with the consultant who was leading the project, designing the add-on and testing it – therefore it was a highly responsive and lean operation. The created add-on is now being rolled out on some of our key projects.”

by Paul Thornton – Rolls-Royce Civil Aerospace MBSE Transformation Lead

Such approach allowed Rolls-Royce to follow the developments and ensured the product was adapted to the real operational needs.

To learn more about Rolls-Royce's MBSE approach, you can also watch this Capella webinar: